Your cart is currently empty!

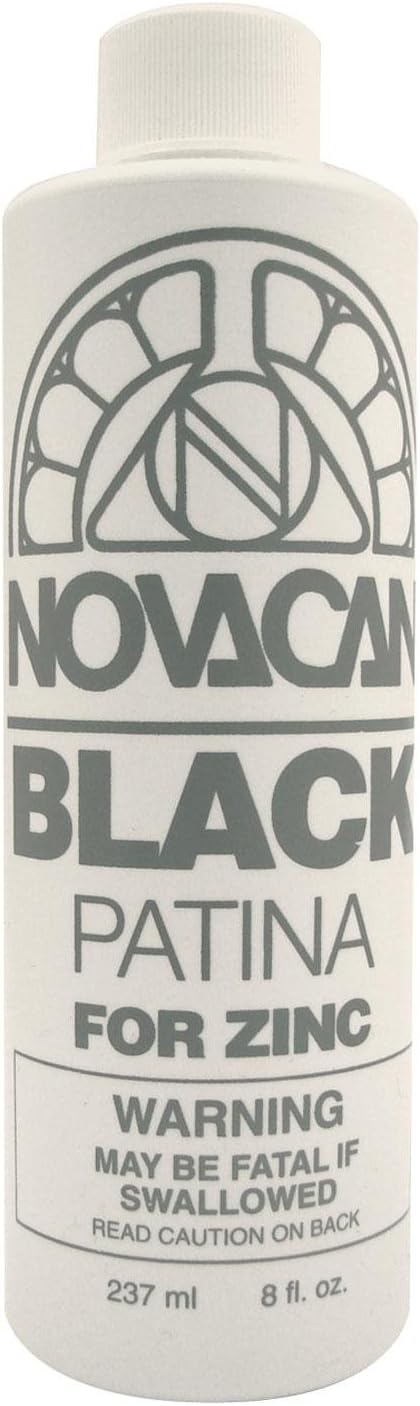

Novacan Black Patina For Zinc 8oz

£12.30

Price: (as of – Details) Use: Produce black finish on zinc came, Size: 8 Oz. bottle. New & improved child resistant safety caps. Rich black patinaDeveloped especially for zinc applications

Cheryl Clutter –

WORKS GREAT

Never disappointed with NOVACAN products givers the material and gives a rich dark finish.

James P. –

Good product

Exactly what I needed. Good product at a good price.We use Amazon for most of our purchases and I update my reviews if anything changes with the products. I do this so other Amazon users can get a real feel for the life of the product. I am not associated with any company and all opinions are my very own.

Amazon Customer –

Black patina

Great product.. work really well on my zinc.

Carol N. –

Stop reading the reviews; buy it and try this zinc patina hack!

You will need:· BOTH Novacan black patina for zinc and black patina for lead and solder· Two small cups or bowls to pour patina solutions out in (the whole bottle will be wrecked if you dip directly into it)· A cheap paint brush like the ones typically sold for soldering paste· Spray flux cleaner such as Kwik Clean· A spray bottle with isopropyl alcohol or acetone· An abrasive such as 3M Contour Surface Sanding Sponge, Super Fine (forget steel wool itâs messy and rusts) cut into 1 inch squares· A vacuum cleaner with a crevice tool if the window is to be grouted· Liquid wax such as Liva Stained Glass Polish· Paper towels· A soft cloth INSTRUCTIONS: The trick is to keep the zinc totally clean from the soldering stage on.1. As soon as one side is soldered, remove every bit of flux immediately using flux cleaner and paper towels before turning over and soldering the other side. If there is absolutely any flux residue left, sand it off using paper towel with cleaner; the zinc can corrode rapidly otherwise and will âbleedâ through the patina.2. Solder and repeat on the other side3. Grout the came and clean with whiting (if applicable) on each side4. Vacuum up whiting with the extra grout, donât brush it off, and repeat that as often as needed during the whole process. Let cement set for at least a day.5. Section by section, on one side at a time, spray alcohol on and sand the came and solder down to a bright brushed polish while wiping off black residue with a paper towel. Discard each sanding block square as soon as it starts to leave even more dark residue. This has to be done very, very thoroughly and without leaving any dark or oily areas, particularly where the flux used to be. After completely sanding the came, spray down with alcohol and rub with paper towel until everything is squeaky clean.6. After cleaning the first side immediately apply patinaâ oxidation can occur in a few hours and you would have to do it over. Pour the patina solutions into separate cups7. Paint a heavy, dripping wet coat of zinc patina all over the came. Donât expect the color to be even, but if there is any beading or crawling of the patina then quickly wipe the patina off on that section and sand with alcohol again before reapplying. Expect the solder to remain somewhat light and the came to be blotchy.8. While it is still wet, paint a heavy coat of lead/came patina which should instantly turn everything a very dark black (yay!)9. Wait until dry and then clean again using a lot of the flux cleaner and a soft cloth very lightly so as not to remove the patina at this stage. This step helps prevent corrosion from the patina. If you accidentally wipe the patina off, reapply. The solder often lightens a bit so once the solder came has been completely cleaned, place a small drop of the lead/solder patina on just the solder where needed. Let everything completely dry.10. Repeat sequence on the other side11. Apply liquid wax in a fairly thick coat, let dry and polish with a soft clothLet me know in the comments how it worked!

Pat –

Stained glass projects

I use the black and copper to patina my srained glass projects. I have never been disappointed.

Marc R. Baril –

An interesting experiment…

This patina works reasonably well if the surface is extremely clean, however I have not been able to achieve the jet black patina one expects with tin/lead, and the finish is very difficult to apply evenly. It is essential to let the surface air-dry before buffing. On the good side; when this product is mixed with a very small amount of black patina solution, the resulting patina is quite beautiful. The result is a very dark, almost black patina with bronze highlights (obviously precipitated copper). It does not have the bright copper character associated with a pure copper patina (CuSO4 soln’), which I find objectionable for most projects. The result was perfect for some windows mounted in dark red/brown wood. So, as far as I’m concerned, this product is no substitute for tinning all the zinc surfaces in my work – but at least I have a use for what I bought!Good seller, product was well packaged to avoid leaks during transport.Update 01-30-13:I know of at least one person who got excellent results with this patina on zinc. The key is to make sure that the surface is absolutely, completely clean.

Renee' in Colorado –

must have in studio workshop

The key in using this patina is proper preparation of the zinc

Amazon Customer –

Evens out stained glass with came.

Just what I wanted